Leading Consumer Products Manufacturer

How prescriptive analytics helped a consumer products manufacturer streamline production and get to market faster

What We Did

A leading consumer products manufacturer was being crushed by excessive overtime costs across its production network and needed to optimize production planning without spending a fortune. The company turned to West Monroe to:

- Audit its production planning processes and programs to identify weak points

- Deploy advanced modeling software to show how smarter decisions could impact the bottom line

3

$80k+

$200k

Project Timeline

The Challenge

Struggling to meet market demand and drowning in overtimes costs, the consumer products manufacturer needed to identify what was going wrong in its production processes and create an improved plan that would balance plant cost and capacity against shipping costs. The company also needed to equip its leadership to make effective decisions about the allocation of production.

The company couldn’t afford to wait for long-term returns and needed assurance that production decisions would be delivered quickly and effectively; the company sought a mechanism to predict the impact of production plan changes before implementing them.

An Undeniable Approach

In order to understand the challenges and issues in production planning, West Monroe first reviewed and assessed the maturity of the manufacturer’s:

- Supply chain planning

- Order management

- Production planning processes

- Transportation planning

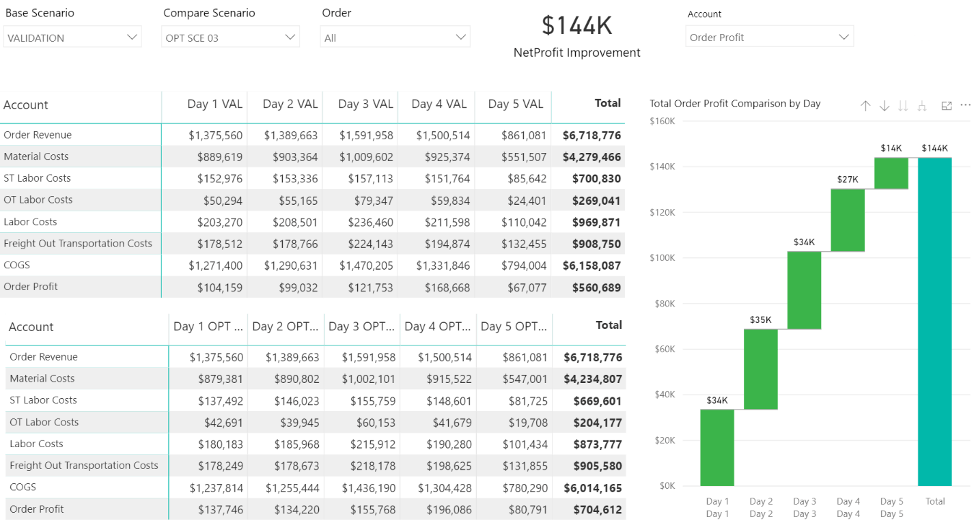

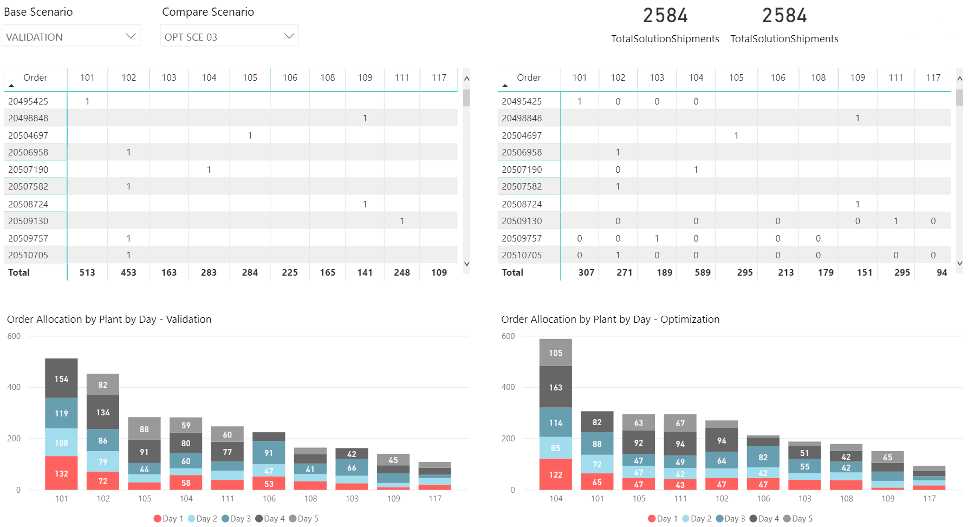

West Monroe used this analysis to identify the precise ways the manufacturer’s current production plan was eroding value and increasing service costs. Then, we created a proof of concept using advanced modeling software that can quickly measure the long-term results of changes to a production plan. We zeroed in on one week of the manufacturer’s historical operational and financial data, enabling us to model the impact of alternative decisions. This model helped the client see how small changes in the present would result in increased efficiency and operational effectiveness in the long-term.

Returns You Can Measure

West Monroe employed an MVP approach to implementing the advanced modeling software to prioritize initial and rapid deployment of specific capabilities that support the company’s daily production planning decisions. With those capabilities in place, the project team will continue building out a robust prescriptive analytics solution that enables the company to reap further benefits.

The MVP approach has already begun to produce savings; the engine will produce significant benefits in three months or less. Once the advanced modeling software capabilities are fully implemented over the next six months, it’s projected to drive weekly savings of $80,000 to $200,000.